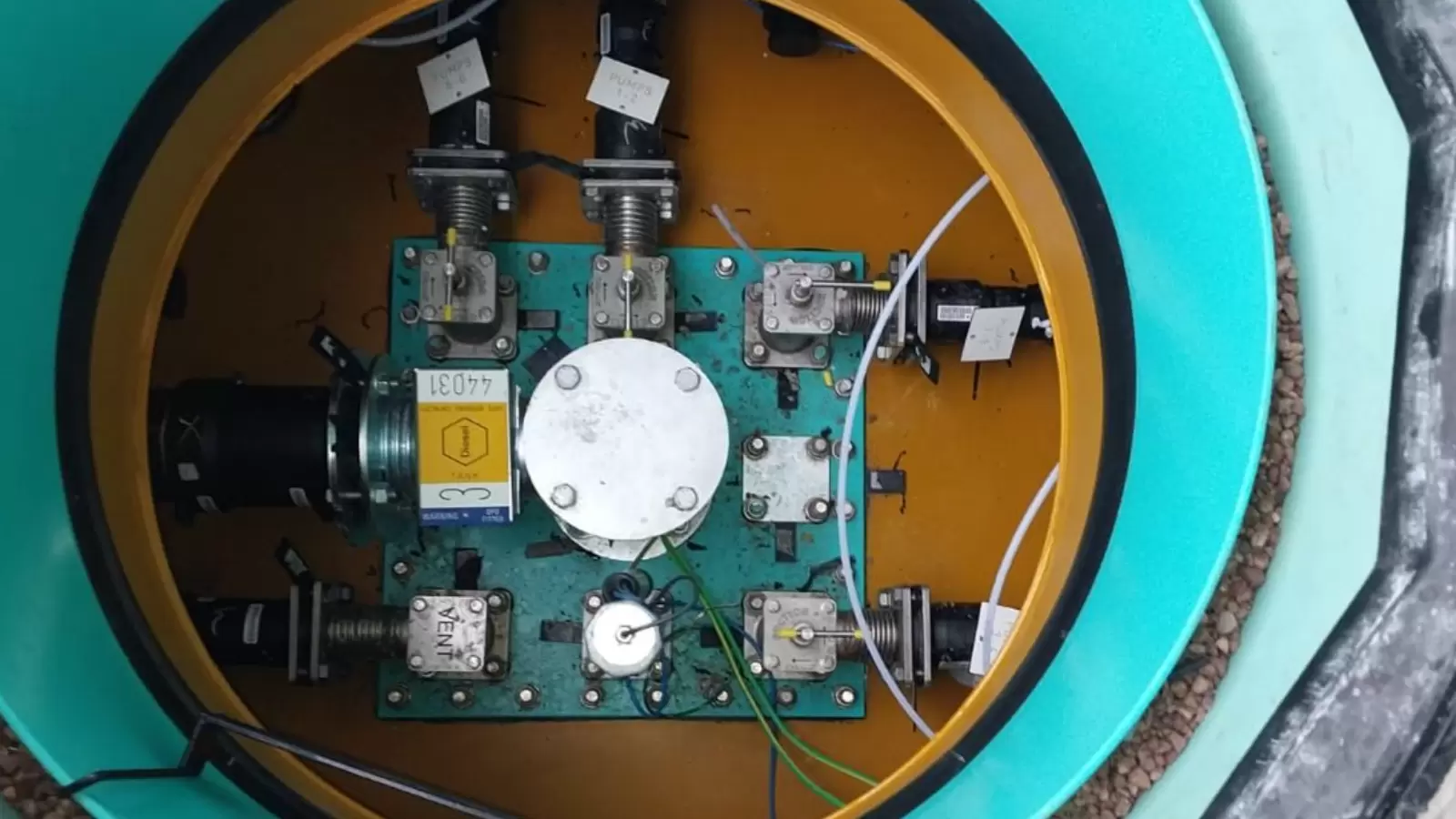

Faster, Safer Builds: Tesco Widnes Bridge Adopts Pre-Engineered ATLAS Chambers.

Accelerating Builds with Pre-Engineered Chambers - (Tesco Forecourt, Widnes Bridge)

Client

At the

Widnes Bridge site, Tesco faced the challenge of delivering a complete

forecourt refuelling infrastructure under a tight timeline and strict cost constraints. Conventional tank chamber systems often require extensive on-site customisation and labour-intensive installation, which can lead to budget overruns and schedule delays.

To overcome

these limitations, the project team selected Berrys Technologies' pre-engineered ATLAS chambers to streamline construction without

compromising quality or performance.

These

modular, factory-assembled chambers offered significant time savings by:

Eliminating

complex on-site fabrication, reducing

labour costs.

Standardising

installation workflows, enabling

faster deployment.

Improving

site safety, with fewer

hours spent in confined underground spaces.

The ATLAS

system is designed for seamless integration with Berrys’ broader forecourt

equipment portfolio, ensuring reliable connectivity between fill points,

venting systems, and pump infrastructure. This cohesive approach allowed the

Tesco team to complete the installation faster, while maintaining full

compliance with safety and environmental standards.

This project

illustrates how

Berrys Technologies pre-engineered solutions support faster, safer, and more

cost-effective fuel infrastructure builds, making them an ideal choice for retailers

operating under high delivery pressure and tight margins.